Ever wonder why some fertilizer plants run so efficiently while others deal with tons of waste and sky-high energy bills? It usually comes down to the production method they use. When it comes to potassium sulfate—a must-have for crops like fruits, vegetables, and tobacco—the Mannheim process really shines. This proven approach, refined over many years, reacts potassium chloride with sulfuric acid to create top-quality potassium sulfate. And it gives you a useful hydrochloric acid byproduct too. If you’re involved in farming, chemicals, or just interested in smart manufacturing, keep reading. We’ll cover five major benefits that make the Mannheim process a favorite. These perks stand out even more when you pair it with solid equipment from trusted suppliers.

What Makes Potassium Sulfate So Essential?

First, let’s get the basics straight. Potassium sulfate, often called SOP, does wonders for growers. It supplies potassium without adding chloride, which can hurt delicate plants. Picture grape vines in California or potato farms in Idaho. SOP helps keep the soil healthy and boosts big harvests. But making it isn’t always easy. The Mannheim process started back in the late 1800s in Germany. It uses high heat in a special furnace to make things happen just right. Today, it produces about half to 60 percent of the world’s SOP supply. That’s millions of tons each year. Now think about a real plant that turns out 160,000 tons of SOP annually, along with 200,000 tons of good HCl. That’s the kind of output we’re talking about.

Advantage 1: Complete Reaction for Maximum Yield

A common problem in SOP production? Reactions that don’t finish fully. That means wasted materials and lower purity. The Mannheim process avoids that issue. It achieves a full reaction between potassium chloride and sulfuric acid. The temperature goes above 600°C inside a muffle furnace. The design provides steady heating. No uneven spots. So everything converts properly.

Imagine workers in a plant in Inner Mongolia. They load materials into the furnace’s center. The reaction happens in two steps. First, it forms potassium bisulfate. Then it turns into sulfate. And it all flows smoothly. Yields often reach 95 percent or better in well-tuned systems. Other methods, like double decomposition, frequently leave things incomplete. They end up with impurities and lesser quality SOP. I remember hearing about one plant that switched to Mannheim. They increased output by 20 percent. And they didn’t even add more workers. That saves cash. It cuts rework and waste disposal too.

- Key Tech Behind It: Better furnace designs with improved flue systems. They recycle heat. This keeps the reaction total.

- Real Impact: You waste less raw material. That can save up to $50 per ton in many cases.

Advantage 2: Low Energy Consumption That Saves Big

Energy costs can hurt profits in chemical plants. The Mannheim process changes that. It uses clever heat management. Gas generators provide the heat. Optimized furnace construction cuts down on coal or fuel. You might save 20 to 30 percent compared to older ways. The flue system makes full use of the energy.

Consider a standard SOP line. Older setups burn a lot of fuel to stay hot. But Mannheim’s improvements, like special materials in the walls, trap the heat inside. Reports from actual plants show low coal use while keeping production steady. Double decomposition needs extra steps for mixing and separating. That drives up energy. Mannheim keeps it simple. A guy I know in the business told me his team slashed energy bills by a third after an upgrade. They used the savings to buy new gear.

Here’s a simple table to compare:

| الجانب | عملية مانهايم | Double Decomposition Method |

| Energy Use per Ton | Low (smart heating) | Higher (extra steps) |

| Fuel Savings Potential | 20-30% | Limited |

| Typical Setup Cost | Fair upfront, low running | Cheaper start, high later |

It’s not just about being eco-friendly. It hits the bottom line hard.

Advantage 3: High-Quality HCl By-Product for Extra Revenue

Don’t waste anything—that’s a core idea in Mannheim. As it makes SOP, it also creates hydrochloric acid. And this isn’t low-grade stuff. It’s pure enough for direct sale. Industries like steel cleaning or water treatment love it. The recovery system captures it. Then it refines the acid. This meets strict environmental rules easily.

Some other methods produce byproducts that are hard to use or worthless. Mannheim’s special absorption setup improves the HCl quality. What could be trash becomes cash. In that Inner Mongolia plant example, they make 200,000 tons of HCl a year. That brings in good money. It often covers 10 to 15 percent of costs. Plant managers I’ve talked to say selling the HCl turned struggling operations profitable. It’s basically two products from one process.

- Boost to Economics: HCl sales can cut SOP costs by up to $75 per ton.

- Environmental Win: It recycles acids. Less waste goes out. Fewer headaches with regulations.

Advantage 4: Durability and Long Service Life of Equipment

No one likes equipment that fails often. The Mannheim process excels here. It uses tough, corrosion-resistant materials in critical parts. Think furnaces and pipes. This leads to fewer stops and lower repair bills over time.

Good suppliers, especially those with patents on furnace upgrades, build systems that last. You can expect 15 to 20 years of service. Cheaper alternatives might only go 10. In one export story from Brazil, a Mannheim line held strong in wet conditions. Others rusted quickly. PLC controls add intelligence. They automate feeds and watch for issues. This prevents damage. It’s dependable. Operators get real peace of mind, especially during busy seasons.

Advantage 5: Easy Operation and Scalable Output

Finally, the Mannheim process is straightforward to run. PLC automation lets you tweak settings quickly. It cuts labor needs and mistakes. Production stays consistent. You can ramp up output without constant oversight.

Other methods can be tricky. They often require experts on site all the time. Mannheim’s uniform heating and full reactions make life easier. That reference plant hits 160,000 tons of SOP yearly without drama. Growing your operation? It’s simple to expand. An industry friend mentioned training new staff in just weeks. The setup is intuitive. And low labor costs make a huge difference in tough markets.

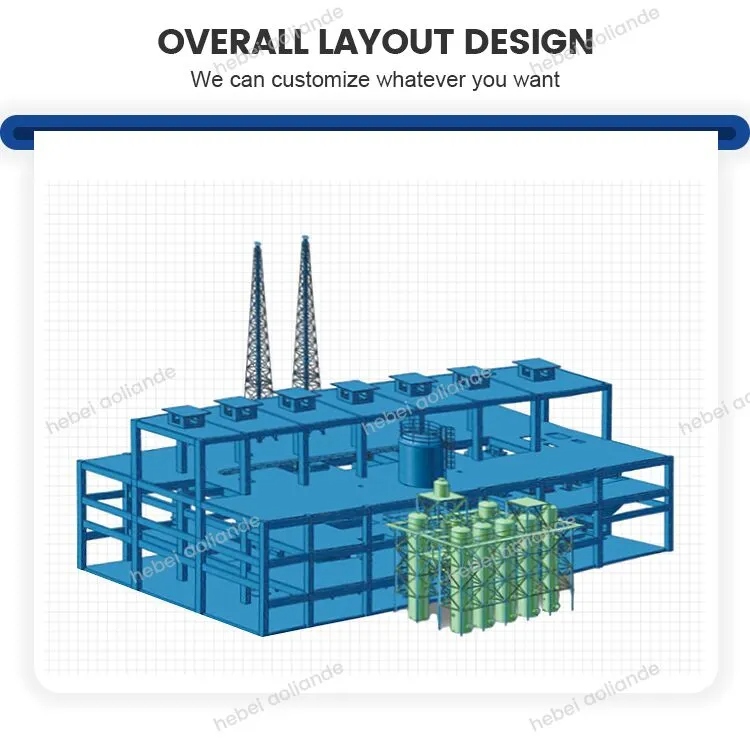

Introducing Aoliande: Your Go-To Supplier for Advanced Production Lines

If the Mannheim process catches your eye, check out أولياند. They’re a strong player in chemical equipment, based in Hebei, China. Since 2016, they’ve focused on Mannheim process potassium/sodium sulfate production lines. They build setups for high-volume SOP plants. But they do more. They supply Hydroxy propyl methyl cellulose production lines (HPMC), calcium chloride production lines, and water soluble fertilizer خطوط الإنتاج. Everything gets tailored to what you need.

They also handle composites. That includes FRP pipe filament winding machines, FRP tank filament winding machines, FRP molded grating machines, FRP pultrusion machines, and FRP rebar machines. These produce tough finished products. Think FRP/GRP pipes, tanks, gratings, pultruded profiles, and even underground fuel tanks. With ISO certifications and exports to places like the USA, Brazil, and India, they prioritize quality and support. They offer tech advice and help with installation. Aoliande makes it easier to bring Mannheim benefits to your facility.

استنتاج

To sum it up, the Mannheim process is more than just a way to make things. It’s a wise choice for efficient and profitable potassium sulfate production. It delivers full reactions for top yields. It uses little energy. And it creates worthwhile HCl byproducts. All this beats options like double decomposition in both tech and money matters. Whether you’re supplying farms or running a chemical site, these advantages pay off. Thinking about an upgrade? Looking into dependable suppliers like Aoliande might be a great step.

الأسئلة الشائعة

What is the Mannheim process for potassium sulfate production?

The Mannheim process reacts potassium chloride with sulfuric acid under high heat in a furnace. It produces potassium sulfate and hydrochloric acid. People know it for full reactions. This leads to high yields and good quality. Real plants reach 160,000 tons yearly.

How does the Mannheim process achieve low energy consumption?

It uses smart furnace designs and gas generators. Heating stays uniform. This cuts fuel by 20-30 percent. The system recycles energy fully. That keeps costs lower than methods with many steps.

Why is the HCl by-product from the Mannheim process considered high-quality?

Advanced absorption systems clean the hydrochloric acid. It becomes pure and ready to sell. This changes potential waste into income. It helps cover costs in potassium sulfate production.

How does the Mannheim process compare to alternative methods for potassium sulfate production?

Double decomposition often has partial reactions and poorer quality. Mannheim provides steady heating, tough equipment, and easy scaling. That’s why it handles 50-60 percent of world supply.

Can the Mannheim process be scaled for larger operations?

Yes, definitely. PLC controls keep things steady. Mannheim lines manage big volumes, like 160,000 tons of potassium sulfate per year. Labor and upkeep stay low too.