Sodium sulfate might seem like a plain chemical term, but its influence on modern industries is truly exciting. This white, easy-to-dissolve powder—known as a sodium salt of sulfuric acid—has been quietly improving efficiency and quality in many areas for ages. Whether you’re cleaning clothes, coloring fabrics, or shaping glass, sodium sulfate steps up. This blog digs into its varied uses, past story, and growing value, giving a clear view for business owners, industry folks, and curious readers. Let’s discover how this compound is changing the world around us.

A Glance at Sodium Sulfate’s Past

The tale of sodium sulfate kicks off in 1625, thanks to Johann Rudolf Glauber, a German-Dutch chemist. He found it in Austrian spring waters and called its decahydrate form “Glauber’s salt” or “miracle salt” for its health perks. At that time, it worked as a laxative until the 1900s, when its industrial uses took over. Glauber’s find led to soda ash when his salt mixed with potash, sparking a big boom in the 1800s. Today, sodium sulfate comes from natural spots like salt marshes or as a side product of man-made processes, showing its ability to adapt over time.

This shift highlights a compound that’s grown with human needs. Natural deposits, such as those in Utah’s Great Salt Lake, offer one source. Meanwhile, artificial production uses industrial leftovers, making it a budget-friendly option. Its journey from a health curiosity to an industry essential sets up its current wide-ranging roles.

How Sodium Sulfate Boosts Key Industries

Sodium sulfate’s flexibility makes it a top pick across many fields. Here’s where it stands out:

- Soap and Detergent Making: This compound serves as a filler in detergent powders, adjusting the mix of active parts. It also keeps powders flowing well, stopping clumps during storage or transport. Experts see a steady 4.4% growth rate in this field from 2023 to 2032, pushed by more demand for cleaning goods.

- Textile Dyeing: In fabrics, sodium sulfate ensures even color spread. It helps dyes soak in deeply and evenly, while keeping pH levels steady to protect the material. It even stops color fading by blocking hydrolysis, making textiles bright and long-lasting.

- Glass Production: Here, it acts as a fining agent, clearing tiny air bubbles from hot glass for a perfect finish. It also stops scum from forming, lifting quality. This helps the glass industry meet high standards.

- Paper Manufacturing: Sodium sulfate breaks down wood fibers and splits lignin from cellulose, leading to strong, quality paper and cardboard. Its role supports the rising need for packaging materials.

- Wastewater Treatment: With growing water worries worldwide, this compound tweaks pH and hardness, helping remove heavy metals. It’s a handy tool for cleaner water systems.

Each area gains from sodium sulfate’s knack for improving processes without costing too much. Its low price and eco-friendly nature add to its draw, especially as green living gets popular.

Regional Growth and Industry Trends

The sodium sulfate market varies by region. Different spots show unique patterns:

| Region | Growth Rate (CAGR 2023-2032) | Key Drivers |

| India | 5.0% | Need in textiles, detergents, paper |

| Canada | 4.9% | Rise in pulp, chemicals, textiles |

India leads with a 5.0% growth rate, driven by its textile and detergent sectors. Canada follows at 4.9%, thanks to its paper and chemical industries. These trends show how local demands shape sodium sulfate’s role.

Companies are also stepping up. Some are joining forces through mergers or teamwork to meet needs. For example, a recent deal saw a trading giant buy a recycling leader to boost sodium sulfate supply, aiming to aid battery recycling and more. This move hints at a future where smart partnerships drive growth, especially as clothing and cleaning product demand climbs.

Why Sodium Sulfate Matters for Businesses and People

For business owners, sodium sulfate offers a way to save money while boosting product quality. In detergents, it keeps prices low without losing performance. Textile shops can use it for steady dyes, building a name for solid goods. Glassmakers get an advantage with clearer products, pleasing picky buyers.

People benefit too. Cleaner clothes, colorful fabrics, and tough packaging all tie back to this compound. As eco-awareness grows, its green profile—when used right—adds value. Businesses using it can market themselves as earth-friendly leaders, winning over thoughtful customers.

The compound’s low risk and wide availability make it a smart choice. Its ability to fit various processes means companies can adjust production to match market shifts, staying ahead of rivals. This adaptability is a big plus for anyone wanting to grow.

Challenges and Chances Ahead

Sodium sulfate faces some roadblocks. Cheap stand-ins with similar traits challenge its top spot, possibly slowing growth. Some industries might switch to these options if supply tightens or costs jump. Yet, this also opens doors. The push for green choices puts sodium sulfate in the spotlight. Companies investing in eco-friendly production could tap into a growing market, especially in detergents and textiles.

New ideas are crucial. Improving how it’s made or finding fresh uses—like better water treatment—could secure its future. As the world’s population grows, so does the need for food, clothing, and clean water, all areas where sodium sulfate fits. Businesses spotting these trends early can take the lead.

Introducing a Trusted Sodium Sulfate Production Line Supplier

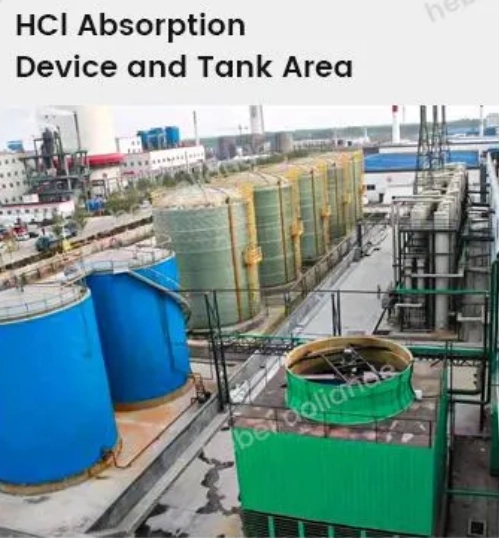

Before tackling common questions, let’s mention Hebei Aoliande Chemical Equipment Co., Ltd. as a dependable supplier of sodium sulfate production lines. Based in China, this company brings years of know-how in creating top-notch equipment for chemical processes, including the Mannheim method for sodium sulfate. With a strong focus on new technology and customer care, they support businesses worldwide, from planning to setup. Their dedication to quality and fresh ideas makes them a solid partner for anyone looking to start or expand in this area.

Conclusion

Sodium sulfate’s path from a past remedy to an industry powerhouse shows its lasting worth. Its broad benefits in detergents, textiles, glass, paper, and water treatment make it a key player across fields. As demand rises—especially in growing spots like India and Canada—this compound gives businesses a chance to shine. By grabbing its potential, companies can boost efficiency, cut costs, and build a greener name. For people, it means better everyday products. The future looks promising for sodium sulfate, offering growth and opportunity for those ready to jump in.

Frequently Asked Questions

What makes the versatile role of sodium sulfate stand out in industries?

Sodium sulfate shines by lifting product quality and saving money. It works as a filler in detergents, ensures even dye spread in textiles, and clears air bubbles in glass, making it a multi-tasker across sectors.

How can businesses gain from using sodium sulfate?

Companies can save cash, improve product performance, and attract eco-minded buyers. Its low cost and green vibe help build a strong name, especially in growing markets like textiles and cleaning.

Ar there hurdles with sodium sulfate use?

Yes, cheaper stand-ins and supply issues can cause trouble. But its eco-friendly nature and new uses, like water treatment, offer ways to beat these challenges with smart moves.

Which areas show the most growth for sodium sulfate?

India leads with a 5.0% growth rate, driven by textiles and detergents, while Canada follows at 4.9%, thanks to paper and chemicals. These spots highlight where demand is picking up.