Key Features of FRP Pultrusion Machines

Advanced Automation Capabilities in Pultrusion Equipment

FRP pultrusion machines lead the way in automation. They combine sophisticated control systems to simplify production tasks. The hydraulic FRP pultrusion production line uses PLC for control and features an LCD screen. It is a full production setup that includes hydraulic reciprocating traction and pneumatic fixed-length cutting. This allows exact management of the manufacturing steps. It results in steady quality products. The machines can alter the winding angle based on customer needs. This improves the making of FRP pultrusion profiles.

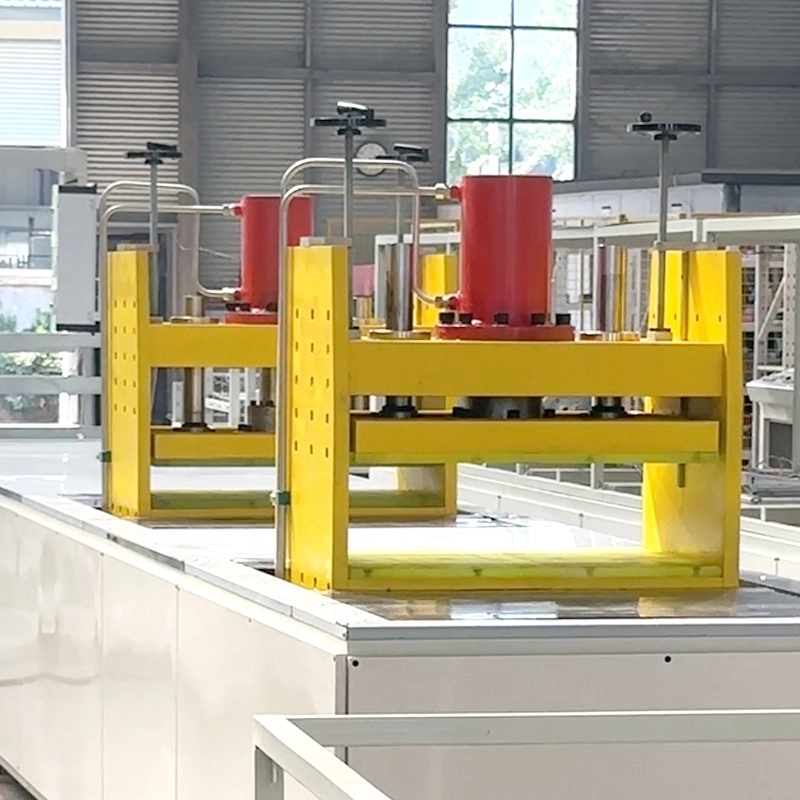

Durability and Reliability of Pultrusion Production Lines

Durability and dependability matter a lot in industrial tools. FRP pultrusion machines perform well in these areas. They use imported hydraulic cylinder seals for a longer lifespan. The hydraulic system has a quiet, energy-saving variable pump. These traits boost work efficiency. They also cut down on stoppages. This makes them a trustworthy option for ongoing production.

Energy Efficiency in Modern Pultrusion Plants

Energy saving is a key trait of today’s FRP pultrusion plants. The hydraulic system’s energy-efficient variable pump helps lower power use. Automatic alerts for oil temperature and oil level issues also aid in this. Plus, digital screens show traction speed. High-accuracy temperature controls ensure smooth running without wasting energy.

Benefits of Using FRP Pultrusion Process

Increased Productivity with Pultrusion Machines

The FRP pultrusion process greatly lifts productivity by automating many manufacturing phases. The complete unit has a creel, dipping tank, mold table, reciprocating tractor, cutting saw, product support rack, and control system. This all-in-one design enables smooth work. It cuts down on human effort.

Cost-Effectiveness of FRP Pultrusion Production Lines

FRP pultrusion machines provide affordable ways to create top-notch profiles. They make the most of materials and reduce waste with precise automation. This leads to big cost savings for makers. Also, the process boosts bending strength and stiffness while keeping weight low. It adds worth to the final item without raising production expenses.

Consistent Quality Output from Pultrusion Plants

A major perk of the FRP pultrusion process is its steady quality results. Temperature control uses high-accuracy tools. This ensures even curing and finishing for all items. Such reliability is vital for uses needing exact parts, like FRP pultrusion grating or structural profiles.

Applications of FRP Pultrusion Technology Across Industries

Construction and Infrastructure Applications

FRP pultruded profiles are widely applied in building work due to their light weight and rust resistance. They suit projects like bridges, walkways, handrails, and other structural parts needing toughness and little upkeep.

Automotive and Transportation Uses

In the car industry, FRP pultruded parts cut weight without losing strength. This helps vehicles use less fuel while staying safe. Transport systems also gain from these materials. They last long even in tough weather.

Electrical and Renewable Energy Solutions

FRP pultrusion technology is crucial in electrical uses like cable trays and enclosures because it doesn’t conduct electricity. In renewable energy fields like wind or solar power, parts such as photovoltaic brackets made this way boost efficiency. They are also eco-friendly.

Aoliande’s Contribution to the FRP Pultrusion Industry

Overview of Aoliande’s FRP Pultrusion Machines

Aoliande is a top name in the FRP pultrusion field. It offers cutting-edge and effective production gear. The hydraulic FRP pultrusion production line uses a PLC control and an LCD screen. It’s a complete setup with hydraulic reciprocating traction and pneumatic fixed-length cutting. This ensures accuracy in making processes. It leads to high-quality products. The machines have high-precision temperature control systems and digital traction speed displays. Operators can tweak the process for the best outcomes.

Aoliande’s FRP pultrusion machines shine due to their flexibility. They can craft many products like FRP pultrusion profiles, photovoltaic brackets, wire troughs, round rods, and hollow panels. The hydraulic traction device has various work modes. It offers adjustable traction speeds for better flexibility. Also, imported hydraulic cylinder seals and energy-saving variable pumps reduce upkeep needs. They ensure lasting durability.

Another key trait is the gear’s ability to use materials well. It increases bending strength and stiffness while cutting weight. This boosts product performance without raising costs. Thus, Aoliande’s machines are perfect for makers wanting to efficiently produce high-performance FRP pultrusion grating or structural parts.

Other High-Performance Products Offered by Aoliande

Beyond its famous FRP pultrusion machines, Aoliande supplies a wide array of high-performance items to meet varied industrial demands. These include:

FRP/GRP Molded Grating Machines

The FRP/GRP molded grating machine has an advanced hydraulic lift system for quick heating and easy handling. It’s built for simple setup and care, making it user-friendly for producers. The machine includes parts like a mixer, storage tank, hydraulic pump, grinding machine, and cooling tower. These pieces work together smoothly to make tough molded gratings with exact sizes.

FRP Rebar Machines

Aoliande’s FRP rebar machines are designed for efficiency in crafting different rebar types. The unit automatically handles tasks like yarn splitting, impregnation, pre-forming, winding, heating and curing, hauling, fixed-length cutting, and stacking. With options for rebar diameters (DN4-40mm), these machines meet specific project needs while keeping quality steady.

Computer-Controlled Filament Winding Machines

The production line has six parts: inner layer manufacturing machine, computer-controlled mortar-winding machine, curing station, repairing machine, mold unloading machine, and resin mix station. Advanced control systems ensure precise winding patterns and cost-effective output.

Complete Set of FRP Winding Molds

Aoliande also provides specialized molds for tanks (DN600-DN4000mm), pipes (DN25-DN2500mm), flanges (DN25-DN1000mm), and elbows (DN25-DN300mm). These molds are made for durability. They support efficient production processes.

Customized Production Lines

Besides standard gear, Aoliande offers tailored solutions like Mannheim Process Potassium Sulphate Making Equipment & technology and water-soluble fertilizer production lines. These unique systems show the company’s dedication to solving specific industrial challenges.

FAQ

Q: What are FRP pultrusion profiles?

A: FRP pultrusion profiles are composite materials made via the pultrusion process. They offer high strength-to-weight ratios suitable for many industrial uses.

Q: How does the FRP pultrusion process work?

A: The FRP pultrusion process pulls raw materials like glass fibers through a resin bath. Then, it heats them in molds to form strong composite structures.

Q: What industries benefit most from FRP-pultruded products?

A: Fields like construction, automotive, transportation, electrical systems, and renewable energy widely use FRP pultruded products for their toughness and efficiency.

Q: Why is FRP pultruded grating preferred over traditional materials?

A: FRP pultruded grating is favored because it’s light yet strong. It resists rust, needs little care, and lasts long.

Q: What makes Aoliande’s FRP pultrusion machines unique?

A: Aoliande’s FRP pultrusion machines have advanced automation features like PLC control systems with LCDs for precise making. They also have durable parts for reliability.

For inquiries or more information about our products: WhatsApp: +86-13363884492 Email: belen@aldfrp.com.