Assessing Your Production Requirements

Evaluating Production Volume and Capacity Needs

When choosing the FRP or GRP rebar machine for your needs. It’s important to consider how much you’ll be producing and what capacity you require. Your production level will dictate the kind of machine that would suit you best. For example, if your work involves making types of FRP rebar, at the same time, a multi-line FRP rebar machine could be a good fit. The FRP rebar machine is capable of creating sizes of FRP rebars by automating processes like separating yarns and prepping them for winding and heating during the curing stage before being cut to the desired lengths and stacked up neatly on the 2-line model for DN 40mm or the 5-line model for DN 26mm efficiently.

Identifying Material Specifications for Your Products

When considering your materials for production, it’s important to take into account the specifications needed for your products, like durability and resistance to rust. Make sure the machinery can handle these requirements effectively. The FRP/GRP rebar equipment is built to fully saturate roving in resin and provides winding speeds to streamline production based on your material requirements. This guarantees uniformity and excellence in every manufacturing cycle.

Considering Space and Infrastructure Constraints

Space availability is frequently. Choosing a machine that fits your location well has a crucial impact. Machines such as the FRP pultrusion production line are quite large (measuring 26 meters in length ) and might necessitate notable changes to your existing infrastructure. Conversely, smaller machines or modular systems could be more suitable for facilities with space constraints.

Features to Look For in an FRP/GRP Rebar Machine

Automation and Technology Integration

In today’s manufacturing industry, automation plays a role in improving efficiency and reducing mistakes in production processes. FRP rebar machines incorporate automation functions like smart temperature regulation in ovens and automated cutting saw systems for accurate length measurements. These functionalities not only boost productivity but also help minimize errors that can occur when tasks are done manually. Moreover, machines with PLC controls and LCD screens offer user interfaces that make it easier to monitor operations effectively.

Energy Efficiency and Environmental Considerations

Ensuring energy efficiency is crucial for cutting down on expenses and complying with environmental guidelines. FRP pultrusion equipment utilizes energy conserving variable pumps, in their hydraulic systems. Furthermore embracing eco manufacturing practices supports worldwide sustainability objectives.

Durability and Maintenance Requirements

The durability of a machine significantly affects how long it will last and the value of your investment over time. Using top notch materials such as stainless steel tanks and molds that resist corrosion can help ensure a lifespan, for the equipment. Having components that are easy to access makes cleaning up resin spills in ovens a breeze simplifying maintenance tasks. It’s important to maintain the machine to keep it running efficiently.

Comparing Different Types of FRP/GRP Rebar Machines

Pultrusion-Based Machines vs. Winding-Based Machines

Machines that use pultrusion techniques are designed to create profiles with strength by adjusting bending stiffness through precise procedures allowing for customization of winding angles to meet specific client needs and preferences.With winding based systems, intricate patterns essential, for applications can be produced, although they may involve a higher level of manual input.

Advantages of Modular vs. Fixed Systems

Modular systems provide flexibility by enabling upgrades as production needs increase over time and are especially beneficial for companies looking to expand in stages while fixed systems offer stability and are typically more budget friendly, in the beginning but may lack versatility in the long run.

Evaluating Costs and Investment Factors

Initial Purchase Cost vs. Long-Term Operational Expenses

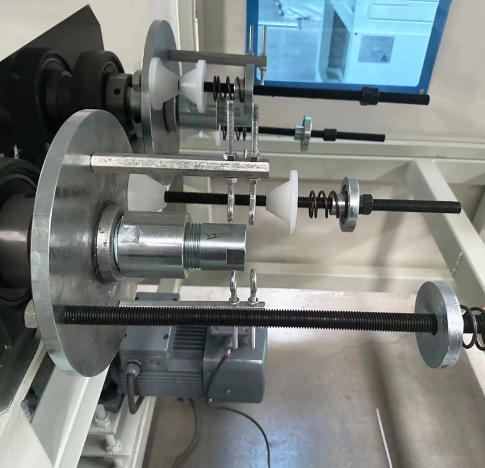

Although the upfront expenses may seem high at glance it’s vital to consider the ongoing operational costs for a complete picture of ownership expenses. Equipment such as the MC. 2500 FRP Mandrel Processing Lathe offers solutions by utilizing integrated designs that simplify production processes. Furthermore the energy efficient features contribute to decreasing utility expenses, in the run.

Financing Options for FRP/GRP Rebar Machines

Getting the right financing can make a difference, in getting top notch equipment without putting too much strain on your cash flow. Plenty of companies there have payment schemes or lease deals designed to suit all kinds of businesses, big or small.

Choosing the FRP or GRP rebar machine requires a detailed evaluation of your production requirements, coupled with thoughtful deliberation on characteristics and expenses for long-term advantages in mind. By matching these elements with your objectives, in mind helps in making a knowledgeable decision that boosts efficiency while upholding product quality expectations.

Selecting a Reliable Manufacturer or Supplier

Researching Manufacturer Reputation and Experience

Choosing a supplier for FRP/GRP rebar machinery is crucial based on their reputation and industry experience as factors to consider An established manufacturer should have a track record of providing top notch machinery and exceptional customer support Aoliande and similar companies provide a wide variety of FRP/GRP equipment such as FRP rebar machinery filament winding machines pultrusion machines Their wealth of knowledge, in this sector guarantees that their products comply with industry regulations and deliver reliable performance.

Reviewing client testimonials and case studies is crucial when assessing a manufacturer’s credibility, along with validating certifications they hold relevant to their industry standards and practices. Manufacturers who demonstrate technology integration,o n as computer-controlled systems, for precise manufacturing tend to distinguish themselves in the market. For instance, the FRP Pipe Production Line developed by Aoliande features Taiwan’s STD industrial control computer system that facilitates automated linearity design and streamlines production processes.

Importance of After-Sales Support and Training Services

When selecting a supplier for your needs, consider thei after-sales support, which plays a role. Efficient machinery operation is ensured through training services, minimizing any potential downtime. Aoliande goes the extra mile by offering detailed technical assistance to help clients enhance their production processes.

Furthermore, having access to parts and maintenance services while also receiving prompt troubleshooting assistance can significantly extend the lifespan of your investment. For instance, machines such as the MCMC–2500RPM and Processing Lathe come equipped with user features that make maintenance tasks simpler. Companies that emphasize ensuring customer contentment frequently provide warranties or service agreements as part of their product packages.

Ensuring Compliance with Industry Standards

Understanding Relevant Certifications and Regulations

Ensuring that FRP/GRP rebar machines meet industry standards is essential without any room for negotiation. Following certifications guarantees that the machinery complies with safety measures well as environmental and performance criteria. For instance, FRP fiberglass reinforced Plastic rebar machinery must adhere to regulations regarding material strengthdurabilityand sustainability.

Within Aoliande range of equipment there are items crafted to fulfill quality standards. Their FRP molded grating device is constructed using top notch materials as 45% steel ensuring longevity and resistance to corrosion. By prioritizing quality Aoliande not boosts the dependability of its products but also guarantees adherence, to international regulations.

Testing and Quality Assurance in Machine Selection

Effective quality control procedures are essential when choosing machinery. Its crucial for manufacturers to offer thorough testing guidelines to ensure the performance and effectiveness of their products prior, to shipping them out. Cutting edge quality assurance features like temperature regulators for ovens or automated tracking systems for cutting saw machines showcase the advanced level of quality management embedded in todays FRP/GRP rebar equipment.

Aoliande hydraulic FRP pultrusion production line is equipped with two display instruments for temperature control and digital speed displays, for improved operational precision to maintain a consistent standard of product quality in every production cycle.

FAQ

Q: What advantages does an FRP/GRP Rebar Machine offer over traditional steel rebar equipment?

A: FRP rebar machines create rebars that’re lightweight but still have strong tensile strength and resistance to corrosion when compared to conventional steel rebars. Moreover these machines come with automation capabilities such, as yarn splitting, impregnation, winding, heating, curing, hauling, cutting and stacking processes being performed automatically (for example Aoliande 2 line model can handle diameters ranging from DN 4 to 40 mm). This leads to decreased labor expenses and enhanced productivity.

Q: Which fiber types can be processed by FRP/GRP Rebar Machines?

A: Many FRP or GRP rebar machines have the flexibility to work with kinds of fibers like glass fiber roving or basalt fiber roving ensuring thorough resin impregnation through a dipping tank system for top notch product performance (for instance Aoliande stainless steel dipping tanks). This versatility enables their use, in industries and applications.

Q: What maintenance is required for FRP/GRP Rebar Machines?

A: It’s important to keep up with maintenance to make sure your machine lasts a long time and runs smoothly! This means cleaning up any resin drips from ovens (which’s easier thanks to split heating boxes) checking gear transmissions for signs of wear in winding devices and swapping out hydraulic seals as needed (for example Aoliande hydraulic systems use imported seals, for extra durability). Don’t forget about calibrating those controllers periodically to keep things running efficiently!

Contact Us

To learn more about the variety of FRP./GRP machinery and other composite material manufacturing options available from Aoliande Company visit our website or contact us via email. Our team is committed to delivering solutions that cater to your individual production requirements while upholding top notch quality standards, in the industry.