The world of construction and industry keeps changing fast. New materials pop up to meet tough demands. Fiber-reinforced plastic, or FRP, and glass-reinforced plastic, or GRP, stand out here. They offer strength without much weight. Machines that make these products play a big role. This blog dives into market insights for FRP/GRP product machines. We focus on three key types: rebar machines, pultrusion machines, and molded grating machines. These tools help create parts for bridges, buildings, and more. If you’re in construction or manufacturing, understanding these trends can guide your choices. Let’s explore the growth, uses, and future of these machines. You’ll see why they’re gaining ground in a busy market.

What Drives the FRP/GRP Product Machine Market

FRP and GRP materials beat out steel in many ways. They resist rust, last longer, and weigh less. This pulls in buyers from various fields. Machines that produce them must keep up with rising needs. Demand comes from big projects like roads and offshore platforms. Governments push for green building too. That means less upkeep and better eco-friendly options. The market feels this shift. Overall, the FRP composites sector hits about $79 billion in 2025. It grows at 5.23% each year toward $102 billion by 2030. Machines fit right in, as they turn raw fibers into useful shapes.

Growth isn’t just numbers. It’s about real-world fixes. In salty air or chemical plants, traditional metals fail quick. FRP/GRP holds strong. Builders save on repairs. That’s a win for budgets and timelines. Plus, lighter parts cut shipping costs. Factories run smoother with these machines. They handle high output without much waste.

Key Market Growth Factors

Several things fuel this boom. First, infrastructure spending rises worldwide. Asia-Pacific leads with fast urban growth. China and India build bridges and towers at a clip. North America follows, fixing old roads with durable fixes.

Second, industries like oil and gas need tough gear. Pipes and platforms face harsh conditions. FRP/GRP machines make parts that don’t corrode. This cuts downtime.

Third, sustainability matters more. These materials use less energy in making and last ages. Governments offer incentives for green choices.

Here’s a quick table of growth drivers:

| Driver | Impact |

| Infrastructure Boom | Boosts demand for rebar and grating in buildings and bridges |

| Corrosion Resistance Needs | Key in chemical and marine sectors for pultrusion parts |

| Lightweight Advantages | Helps in transport, lowering fuel use |

| Eco-Friendly Push | Aligns with global green standards, extending product life |

These factors create steady demand. Machines see more orders as projects scale up.

Challenges in the Market

No market runs smooth. Raw material prices swing. Resins and fibers cost more sometimes. This hits machine makers hard. They pass costs to buyers.

Standards vary by country. Some places require strict tests. That slows entry for new players.

Competition heats up too. Big firms invest in better tech. Small ones struggle to match.

Still, opportunities outweigh hurdles. Innovation in automation helps. Machines get faster and smarter. Buyers look for reliable suppliers who adapt.

Spotlight on FRP/GRP Rebar Machines

Rebar machines shape fibers into bars for concrete. These bars reinforce structures without rusting. Steel bars often fail in wet or salty spots. FRP/GRP rebar lasts longer. Machines pull fibers through resin and cure them into strong rods.

This segment grows quick. The FRP rebar market reaches $4.74 billion in 2025. It climbs to $15.38 billion by 2034 at 14% yearly. Why so fast? Bridges and highways need upgrades. Old steel corrodes, raising repair bills. FRP/GRP cuts that risk.

Applications and Benefits

Builders use these machines for highways, marine docks, and water plants. In bridges, rebar holds up under heavy loads. No rust means fewer cracks over time.

Benefits shine in tough spots. Saltwater eats steel fast. FRP/GRP resists it. Weight drops too—up to 75% lighter. That eases handling on site.

Factories like these machines for steady output. They make bars in various sizes. Custom needs fit easy.

Bullet points on top uses:

- Highway barriers: Strong hold without added weight.

- Waterfront structures: Fights corrosion from waves.

- Water treatment: Handles chemicals without breaking down.

- Buildings in harsh climates: Keeps integrity in rain or snow.

These apps show versatility. Market insights point to more adoption in emerging spots.

Trends Shaping Rebar Machine Demand

Tech advances lead here. New resins boost strength. Machines now automate pulling and curing. This speeds production.

Carbon fiber mixes grow popular. They offer extra pull strength over glass. Basalt fiber emerges too—tough and cheap.

Sustainability trends help. Longer life means less waste. Governments back this with rules.

Challenges? Upfront cost tops steel. But long-term savings win out. Awareness spreads as projects succeed.

Exploring FRP/GRP Pultrusion Machines

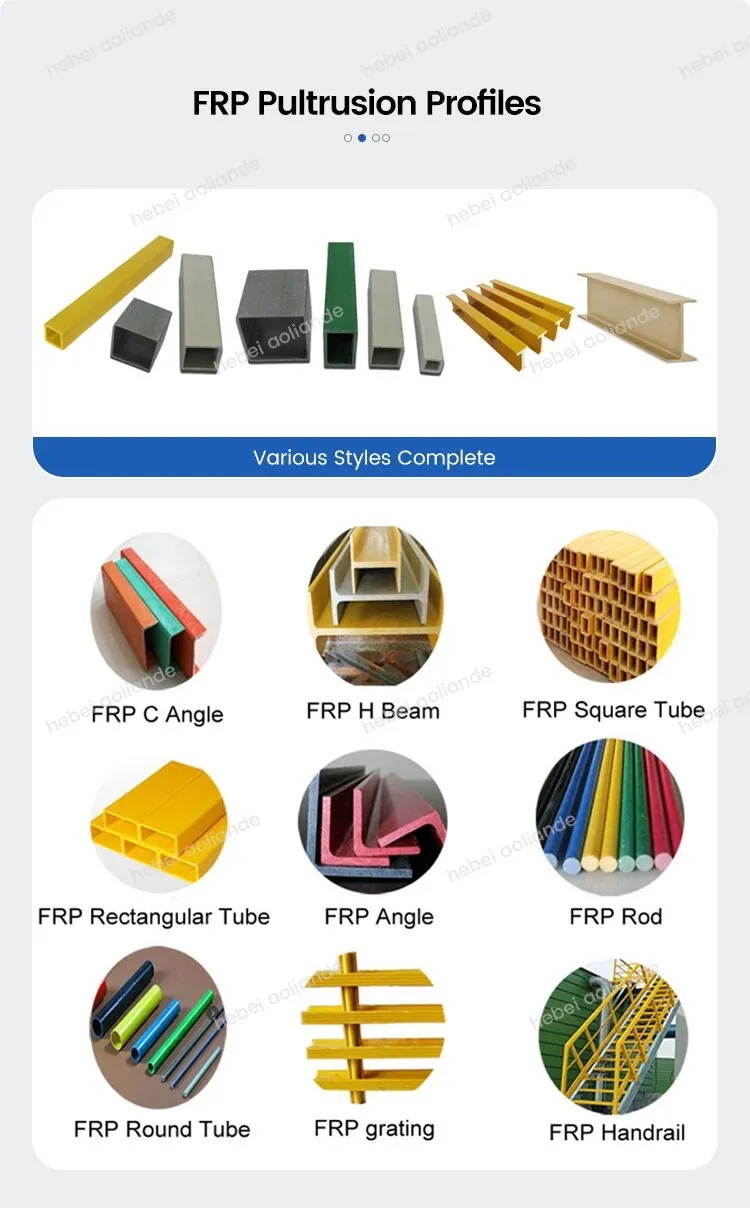

Pultrusion machines pull fibers through resin baths. Heat cures them into profiles like beams or channels. This process makes uniform, strong parts. It’s great for long runs.

The market for these machines hits $64.6 million now. It heads to $101 million by 2031 at 6.7% growth. Profiles from pultrusion find homes in construction and autos.

Why pultrusion? It wastes little material. Parts come out consistent. Speed beats other methods.

Wide-Ranging Applications

Construction takes the lead. Beams support roofs without sagging. They’re light, so install quick.

Auto makers use them for frames. Less weight means better gas mileage. Aerospace grabs some too—for panels that endure stress.

Energy sector loves them. Wind turbine blades need tough, light parts. Pultrusion delivers.

Other spots: Electrical poles and railings. They stand up to weather.

Key apps in bullets:

- Building frames: Replaces heavy steel easily.

- Vehicle parts: Cuts fuel needs in trucks.

- Utility poles: Resists storms and rot.

- Renewable energy: Shapes for solar mounts.

These uses drive machine sales. Buyers seek reliable output.

Growth Trends and Innovations

Automation ramps up. Sensors check resin flow. This cuts errors.

Hybrid fibers mix glass and carbon. Stronger profiles result. Machines adapt with new dies.

Asia-Pacific booms. Factories there multiply. Demand for cheap, fast production rises.

Eco-trends push recycled resins. Pultrusion fits, using less energy.

Hurdles include die costs. But efficiency pays back. Market insights show steady climb.

Understanding FRP/GRP Molded Grating Machines

Molded grating machines press resin and fibers into grids. These grids form platforms or covers. Open design lets fluids drain. Strength comes without much weight.

The grating market starts at $895.5 million in 2025. It grows to $1.5 billion by 2033 at 6.8% CAGR. Machines make gratings for floors and trenches.

Molding suits complex shapes. It’s one-piece, so strong bonds.

Key Applications in Industry

Walkways top the list. Factories need safe paths over wet floors. Gratings grip well, cut slips.

Chemical plants use them. Acids don’t harm the material. Offshore rigs too—for decks that take salt.

Water treatment fits. Gratings cover drains without rust.

Bullets for main uses:

- Industrial floors: Handles heavy steps.

- Trench covers: Lets water flow, blocks debris.

- Marine platforms: Stands up to waves.

- Cooling towers: Resists heat and moisture.

These roles boost machine need. Safety codes favor them.

Emerging Trends for Grating Machines

Custom sizes grow. Machines tweak molds for jobs. This meets varied needs.

Anti-slip tops add safety. Colors match sites too.

Sustainability hits here. Recycled fibers cut waste. Gratings last, so replace less.

Market challenges: Initial price over metal. But low upkeep wins.

Growth looks solid. Infrastructure pushes more grating use.

Introducing Hebei Aoliande Chemical Equipment Co., LTD. as a FRP/GRP Product Machine Supplier

Hebei Aoliande Chemical Equipment Co., LTD. leads in FRP/GRP product machines. With years in the game, they make rebar, pultrusion, and grating gear. Their setups handle custom needs, from design to install. Over 300 staff ensure quality. Products go to places like the US, Brazil, and India. They hold ISO certifications for trust. Buyers get full service—advice, shipping, and setup help. This makes them a solid pick for reliable machines.

Conclusion

The FRP/GRP product machine market offers real promise. Growth in rebar, pultrusion, and grating segments shows strong demand. These tools meet needs for durable, light parts. As industries shift to sustainable options, machines like these will shine. Stay ahead by picking quality suppliers. Your projects will benefit from less hassle and longer life.

FAQs

Q: What market insights show for FRP/GRP product machines in 2025?

A: The sector grows steady, with values around $79 billion overall. Focus areas like rebar hit $4.74 billion, driven by infrastructure needs.

Q: How do FRP/GRP rebar machines fit into current trends?

A: They lead in corrosion-free building. Demand rises 14% yearly for bridges and marine work, offering long-term savings.

Q: What growth can we expect from FRP/GRP pultrusion machines?

A: Machines reach $101 million by 2031 at 6.7% growth. They’re key for light profiles in autos and energy.

Q: Where are FRP/GRP molded grating machines most used?

A: In factories and plants for safe walkways. The market climbs to $1.5 billion by 2033, thanks to durability.

Q: Why choose suppliers for FRP/GRP product machines now?

A: With trends toward green materials, good machines cut costs and boost efficiency in tough apps.