Ever thought about how fertilizers get made? Potassium sulphate plays a big role in farming. It helps plants grow strong. If you run a chemical plant or farm business, knowing the gear for making it matters. This post dives into plant equipment for potassium sulphate production. We focus on the Mannheim process. It’s common and effective. You’ll learn the basics, key machines, perks, and tips. Let’s break it down.

What is Potassium Sulphate and Why It Matters

Potassium sulphate, or SOP, boosts crops. It has potassium and sulphur. Both help plants. Unlike other fertilizers, it fits low-chloride needs. Think fruits, veggies, tobacco. Global demand rises as farms seek better yields.

Production uses methods like Mannheim. It reacts potassium chloride with sulphuric acid. High heat involved. Results in SOP and hydrochloric acid. This way supplies 50-60% of world SOP. Costly due to raw materials. But reliable.

Why care about equipment? Good gear means steady output. Less waste. Better quality. For plant owners, right machines cut costs long term.

The Mannheim Process Explained

Mannheim process stands out. It’s two steps. First, potassium chloride meets sulphuric acid. Forms potassium bisulphate. Then, more potassium chloride turns it to SOP. Happens in a furnace over 600°C.

Raw stuff pours into muffle furnace center. Heat drives reaction. Gas by-product: HCl. Captured for use or sale.

Improvements help. Better furnace build for even heat. Complete reactions. Low energy use. New materials for acid absorption. Boosts efficiency. Fixes environment issues.

Process equation: 2 KCl + H2SO4 → K2SO4 + 2 HCl. Simple. But needs precise control.

Key Plant Equipment in Potassium Sulphate Production

Equipment makes or breaks production. Here’s main pieces.

Furnace and Reactor Systems

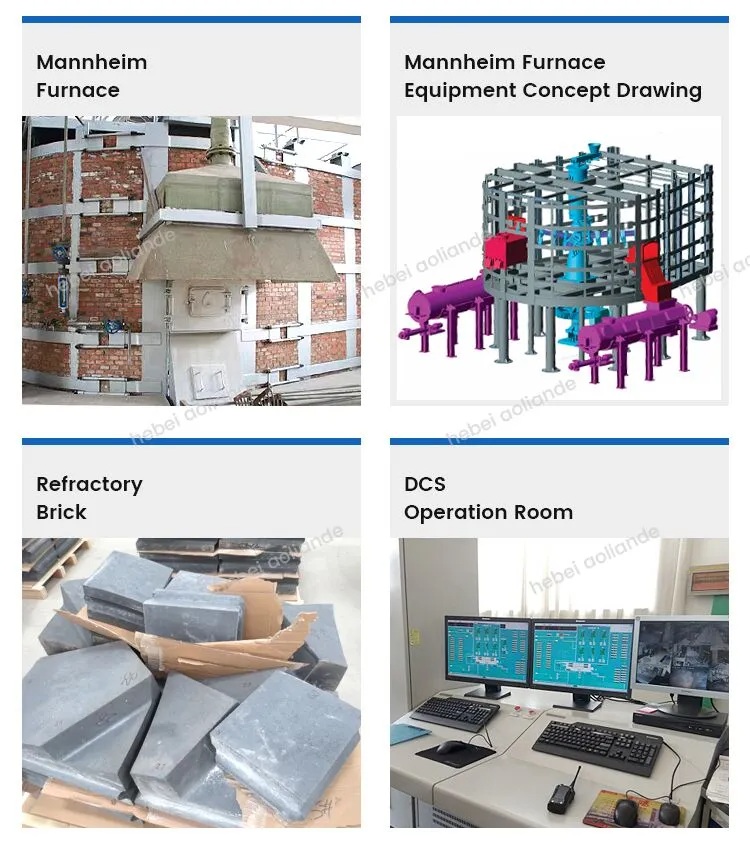

Heart is Mannheim furnace. Muffle type. Heats to high temps. Built with special materials. Resist corrosion. Durable.

Key parts:

- Muffle chamber: Holds reaction. Even heating key.

- Heating system: Gas generators now common. Replace old methods. Save fuel.

- Flue design: Improved for energy use. Recycles heat.

Reactor handles steps. Ensures complete mix.

Feeding and Handling Systems

Raw materials need steady feed. Potassium chloride, sulphuric acid.

Equipment includes:

- Conveyors: Move solids.

- Pumps: For acids.

- Mixers: Blend before furnace.

PLC controls adjust ratios. Saves labor. Keeps consistent.

Waste Recovery and Absorption Units

HCl by-product valuable. But handle careful.

- Absorption towers: Catch HCl gas. Make acid for sale.

- Scrubbers: Clean emissions. Meet green rules.

Waste system recycles. Cuts pollution.

Cooling and Separation Equipment

After reaction, cool product.

- Coolers: Bring down temp.

- Crushers: Break lumps.

- Screens: Separate sizes.

Ensures pure SOP.

Control and Automation Systems

Modern plants use PLC. Auto control.

Monitors temp, pressure, flow. Adjusts real time. Reduces errors.

| Equipment Type | Main Function | Benefits |

| Mannheim Furnace | Reaction chamber | Even heating, low energy |

| Feeding Systems | Material input | Consistent feed, less waste |

| Absorption Units | HCl recovery | Environment friendly, extra revenue |

| Cooling Units | Product handling | Quality control, easy packaging |

| PLC Controls | Overall operation | Saves labor, steady output |

This table shows how pieces fit.

Advantages of Modern Plant Equipment

Good equipment pays off.

Corrosion resistant parts last long. Special alloys in key spots.

Energy savings from better flues, gas heaters.

High output. Plants hit 160,000 tons yearly.

Easy run. Stable process. Less downtime.

Green perks. Recycle HCl. Low emissions.

For businesses, means lower costs. Better product. Happy customers.

- Long life for machines.

- Less fuel use.

- High purity SOP.

- Safe operations.

Challenges in Potassium Sulphate Production

Not all easy. High temps challenge materials.

Acid handling risks corrosion.

Energy costs high if old gear.

Environment rules strict. Need good scrubbers.

Raw material prices fluctuate. MOP and acid expensive.

Solutions? Upgrade equipment. Use new tech. Like improved absorption.

Train staff. Regular checks.

Tips for Setting Up or Upgrading Your Plant

Planning a plant? Start with needs. Output size?

Choose supplier with EPC. Covers design to install.

Look for patents. Shows innovation.

Visit factories. See real runs.

Budget for maintenance. Keeps running smooth.

Go auto. PLC cuts errors.

Test raw materials. Ensures quality.

Introducing Hebei Aoliande Chemical Equipment Co., Ltd.: Your Mannheim Process Potassium Sulfate Production Line Supplier

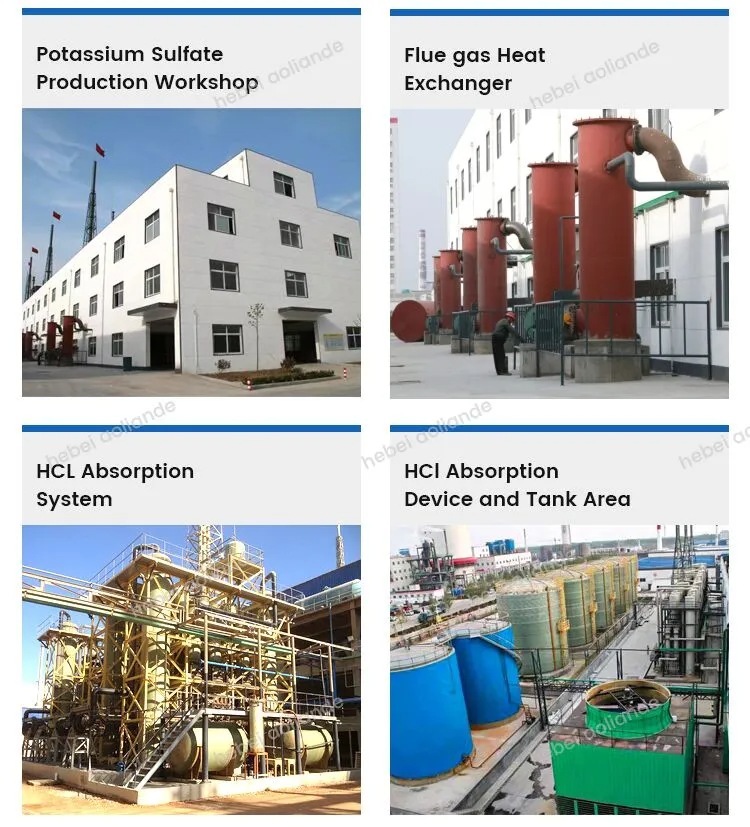

Need trusted source? Hebei Aoliande Chemical Equipment Co., Ltd. fits. Based in Hengshui, China. Pros in Mannheim process lines.

300 staff. 10 R&D engineers. Passed ISO9001, ISO14001, OHSAS18001.

Own factory in Inner Mongolia. 160,000 tons SOP yearly. 200,000 tons HCl.

Offer full EPC. Design, supply, install.

Exported to USA, Brazil, Japan, more.

Patents on improvements. Like better furnaces.

Contact for custom lines. Technical advice free.

Conclusion

Investing in the right plant equipment is the cornerstone of efficient and profitable potassium sulphate production. As detailed, the Mannheim process, while chemically straightforward, demands robust, corrosion-resistant machinery—from the core muffle furnace and precise feeding systems to efficient HCl recovery units and automated controls. Modern equipment directly translates to tangible benefits: higher purity SOP, significant energy savings, reduced environmental impact through by-product recovery, and the ability to scale up to meet global demand. For any operation, whether setting up a new facility or upgrading an existing one, prioritizing high-quality, engineered solutions ensures long-term reliability, lower operating costs, and a strong competitive edge in the agricultural market. By partnering with an experienced supplier, you can transform the complex challenges of potassium sulphate production into a streamlined and successful operation.

FAQs

What is the main plant equipment in potassium sulphate production?

Key includes Mannheim furnace, feeders, absorption units. All for efficient runs.

How does Mannheim process work in potassium sulphate production?

Reacts KCl with H2SO4 in hot furnace. Makes SOP and HCl.

What advantages come from modern plant equipment for potassium sulphate production?

Longer life, energy saves, high output. Plus green benefits.

Why choose Hebei Aoliande for Mannheim process lines?

They supply full setups. Own factory. Global exports.

Can plant equipment handle large potassium sulphate production?

Yes. Scales to 160,000 tons yearly. Custom designs.