Glass making forms common things. These include windows and bottles. Factories always look for methods to make the work easier. They also aim to improve the end item. Sodium sulfate in glass manufacturing shines as a main part that aids in reaching these aims. People call this stuff salt cake a lot. It has a big part in changing basic stuff into clear, tough glass. This post looks at its top pluses. And it shows how it works in the steps.

Lots of glass plants count on it to save money and raise standards. Let’s explain what makes it handy.

What is Sodium Sulfate?

Sodium sulfate appears as a white, crystalline powder. It comes from natural sources or industrial byproducts. In glass making, it acts mainly as a flux and fining agent. Flux means it helps lower the temperature needed to melt silica sand, soda ash, and limestone—the core mix for glass.

Without it, melting would take more heat and time. Factories use anhydrous forms for better control. This setup ensures the batch melts evenly.

Historical Use in the Glass Industry

Glass workers started using sodium sulfate as fining agent in glass more than 100 years ago. At first, it aided in getting rid of bubbles from hot glass. This made smoother pieces. Back in the 1800s, factories in Europe began using it a lot. They did this to handle growing need for clear windows and jars.

Now, it stays common. Lines for making glass use new ways to deal with it well. This change links to bigger factory moves to save power.

With a good understanding of its basics, we can check out how it gives true help in current systems.

Key Benefits of Sodium Sulfate in Glass Production

Adding sodium sulfate changes the game for glass manufacturers. It tackles common challenges like high energy use and defects. Here’s a closer look at its top advantages.

Reduces Melting Temperature

One standout perk is how sodium sulfate reduces melting point in glass. By mixing in about 5-10% of the batch, it drops the required heat from around 1500°C to 1400°C. This cut can save up to 15% on fuel costs, based on data from large-scale operations.

Lower heat also means less wear on furnaces. Plants report extended equipment life by 20%. In a busy factory, that translates to fewer shutdowns and steady output.

Improves Glass Clarity and Quality

Benefits of sodium sulfate in glass production shine through in the final look. As a fining agent, it releases gases that lift tiny bubbles to the surface. Result? Clearer glass without spots.

In bottle making, this leads to fewer rejects—down by 10% in some cases. The even melt prevents streaks, making products stronger too. Tests show treated glass withstands impacts better.

Cost Savings and Efficiency Gains

Beyond quality, it trims expenses. Cheaper than some alternatives, sodium sulfate fits tight budgets. Factories using it see production speeds rise by 10-15%.

Here’s a quick comparison:

| Aspect | Without Sodium Sulfate | With Sodium Sulfate |

| Melting Temp | 1500°C | 1400°C |

| Energy Use | High | 15% Lower |

| Bubble Removal | Manual Fining Needed | Automatic Gas Release |

| Output Increase | Baseline | Up to 15% |

These gains build a stronger bottom line. Workers handle less rework, focusing on core tasks.

These benefits don’t happen in isolation. They tie directly into the hands-on steps of glass making.

The Processes Involved in Using Sodium Sulfate

Incorporating sodium sulfate glass manufacturing process follows a structured path. From raw mix to finished panes, each stage leverages its properties.

Batch Preparation and Mixing

It starts with weighing ingredients. Silica sand takes 70%, soda ash 15%, and sodium sulfate 5-10%. Mixers blend them dry to avoid clumps.

In automated lines, conveyors feed the batch into hoppers. Precision here prevents uneven melts later. Factories check purity levels to hit specs.

Melting in the Furnace

The mix heads to the furnace. Heat ramps up, and sodium sulfate flux in glass making kicks in. It reacts with silica, forming a liquid pool faster.

Temps hold steady at 1400°C for hours. Stirring ensures full integration. Gas emissions from sulfate help purge impurities like iron traces.

Refining and Forming

Post-melt, refining removes last bubbles. Sodium sulfate in glass fining process excels here, as decomposition gases rise and escape.

Molten glass then flows to molds or rollers. Cooling sets the shape. Quality checks spot any flaws early.

This sequence keeps things running smooth. But modern demands add another layer: sustainability.

Environmental Considerations in Sodium Sulfate Use

Glass production impacts the environment, yet uses of sodium sulfate in glass industry can ease some burdens. Lower melting points mean less fuel burned, cutting CO2 emissions by 10-20 tons per 1000 tons of glass.

Recycling sulfate from waste streams fits circular models. Plants treat effluents to reuse water. Regulations push for cleaner methods, and sodium sulfate aligns well.

Proper handling avoids dust issues. Vent systems capture gases, meeting air quality standards.

For those in the field, sourcing reliable supplies matters. Check out our products for options that fit these needs.

Meet Hebei Aoliande Chemical Equipment Co., LTD.

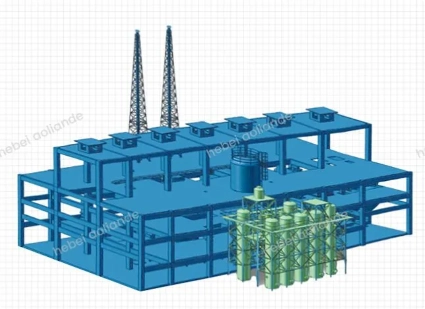

As a trusted name, Hebei Aoliande Chemical Equipment Co., LTD. supplies Sodium Sulfate Production Lines. Based in Hengshui City, Hebei Province, China, the company started in 2016. They focus on Mannheim process equipment, delivering high-purity output. With ISO9001, ISO14001, and OHSAS18001 certifications, they offer full services from design to installation. Their lines produce up to 160,000 tons annually, serving global markets. For glass makers, this means steady, quality sulfate supply. Learn more on our about page.

Conclusion

Sodium sulfate proves essential for efficient, high-quality glass output. Its role in lowering costs, enhancing clarity, and supporting green practices makes it a go-to choice. Factories adopting it see real improvements in daily operations. As the industry grows, its value only increases.

FAQs

What role does sodium sulfate as fining agent in glass play?

It releases gases during melting to remove air bubbles, resulting in clearer glass. This step cuts defects and boosts product appeal in markets like packaging.

How does sodium sulfate reduce melting point in glass affect energy use?

By dropping the temperature needed, it saves on fuel—often 15% less. A plant running 24/7 notices big drops in bills. See details in our production line overview.

Are there environmental perks to using sodium sulfate in glass industry?

Yes, lower heat means fewer emissions. Plus, sourcing from efficient lines like those at sopplant.com supports waste recovery, aligning with strict rules.

What’s the typical amount of sodium sulfate in glass manufacturing process?

Usually 5-10% of the batch. This ratio balances fluxing without excess residue. Adjustments depend on glass type, like flat or container.

Can sodium sulfate flux in glass making work with recycled materials?

Absolutely. It mixes well with cullet, helping melt recycled glass faster. This approach reduces raw material needs by 20-30% in some setups.