What is FRP Rebar?

Definition and Composition of FRP Rebar

FRP, or Fiber Reinforced Polymer rebar, is a sturdy material that strengthens concrete buildings. It’s made of strong fibers, like glass, carbon, or basalt, mixed into a plastic-like base. These fibers make the rebar tough. The plastic base keeps the fibers together and protects them from things like rain or air. FRP rebar is a good choice over steel. People pick it because it doesn’t get rusty.

Comparison of FRP Rebar with Traditional Steel Rebar

FRP rebar is better than steel rebar in many ways. Steel gets rusty when it’s wet or near chemicals. But FRP rebar stays tough and doesn’t rust. This makes it great for places like beaches, bridges, or factories. Also, FRP rebar is super light compared to steel. It’s easier to move and carry, which saves money. But steel bends better when under heavy weight. FRP rebar can be a bit stiff and might break more easily.

How to Produce FRP Rebar?

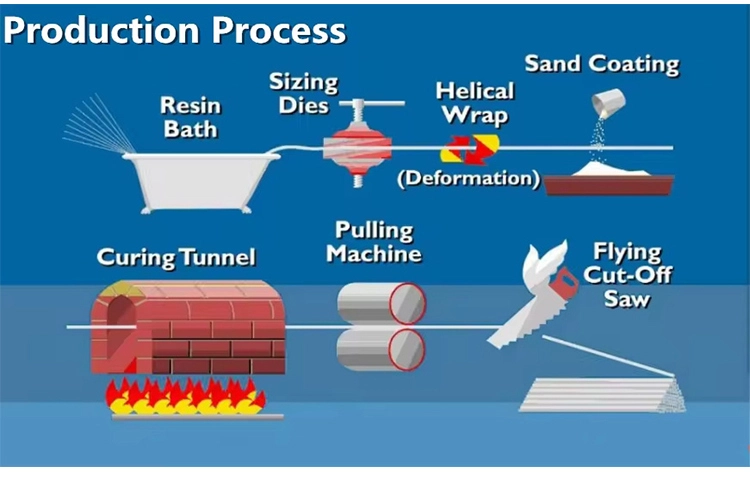

Overview of the FRP Rebar Manufacturing Process

Making FRP rebar takes a few steps to ensure it’s strong and works well. First, workers split fibers into thin pieces. Then, they dip these fibers in a sticky liquid called resin. This happens in a special tank to coat the fibers fully. Next, the fibers are shaped into the right form. After that, they’re wound up and heated in an oven to get hard. Finally, the rebars are pulled out, cut to the right size with a smart saw, and stacked for pickup.

Key Components of an FRP Rebar Machine

The FRP rebar machine is super important. It makes the process easy and keeps the quality high. The machine handles splitting fibers, dipping them in resin, shaping, heating, and cutting. Every part works together to make strong rebars. Aoliande builds these machines to be dependable and simple to use.

Pultrusion Technology in FRP Production

Pultrusion is a neat way to make FRP rebar and other shapes. Workers pull fibers through a bath of resin. This soaks the fibers well. Then, the fibers go through a hot mold to shape and harden them. This process makes the rebar strong and even all the way through.

Resin Impregnation and Curing Process

The resin-dipping step makes sure fibers are fully coated with resin. This helps them stick together nicely. After dipping, the fibers are heated in an oven to set the resin. Aoliande’s FRP rebar machines have clever controls to keep the oven at the perfect temperature. This makes sure the rebar hardens just right.

Benefits of FRP Rebar

Corrosion Resistance and Durability

FRP rebar’s best feature is that it doesn’t rust. Steel rebar can get weak when it’s near water or chemicals. But FRP rebar stays strong in tough spots like beaches or factories. This makes it last a long time and saves money on fixes.

Lightweight Properties and Ease of Handling

FRP rebar is light—about one-fourth as heavy as steel. This makes it super easy to move and set up at building sites. Workers can carry it without big machines, which cuts costs. Plus, it’s simple to ship to far-off places.

High Tensile Strength and Flexibility

Even though it’s light, FRP rebar is very tough. It can hold as much weight as steel or even more. It’s also bendy, so builders can shape it into different forms without breaking it. This makes it handy for all kinds of projects.

Types of Rebar

Overview of Commonly Used Rebars

Rebars come in different types, each good for certain jobs based on how they work.

Steel Reinforcement Bars

Steel rebars are common because they’re easy to get and not too pricey. They bend well under pressure, which is great for some projects. But they can rust when wet or near strong chemicals. This can make structures weaker over time.

Glass Fiber Reinforced Polymer (GFRP) Bars

GFRP bars use glass fibers in a plastic base. They’re light but strong and don’t rust. This makes them awesome for projects needing tough, lightweight materials, like bridges or beach buildings.

Carbon Fiber Reinforced Polymer (CFRP) Bars

CFRP bars use carbon fibers, which are super strong for their weight. These bars are used in fancy projects, like airplanes or important buildings, where top strength is needed. They’re stronger than GFRP but cost more.

Basalt Fiber Reinforced Polymer (BFRP) Bars

BFRP bars come from basalt, a rock from volcanoes. These bars handle heat well and are strong. They’re cheaper than CFRP bars but still work great for many projects. They’re a nice mix of strength and cost.

Applications of FRP Rebar

Use in Infrastructure Projects

Bridges and Highways

FRP rebar is a big help for projects like bridges and highways. It doesn’t rust, even when it’s near road salts or rain. This makes it perfect for buildings that face bad weather. Steel can rust and get weak, but FRP rebar keeps structures strong for years. This means fewer repairs and lower costs. Also, its light weight makes it easier to move and set up, saving time and money.

Marine Structures and Coastal Defenses

Saltwater and wet air can wreck materials in coastal areas. FRP rebar is used a lot in piers, seawalls, and other coastal defenses because it doesn’t rust. It stays tough even when it’s always wet. This makes it a top pick for protecting beach areas. Its strength means structures last longer without needing lots of repairs.

Role in Industrial and Commercial Construction

Chemical Plants and Wastewater Treatment Facilities

In places like chemical plants or wastewater facilities, materials deal with harsh chemicals. Steel rebars can break down in these spots. But FRP rebar fights off chemicals, so it’s great for these projects. It stays strong and safe, making sure buildings last a long time without pricey fixes.

Why Choose Aoliande?

Expertise in Customizing FRP Rebar Machines for Unique Needs

Aoliande is awesome at making FRP rebar machines that fit special project needs. The FRP rebar machine does it all: splitting fibers, dipping them in resin, shaping, winding, heating, curing, cutting, and stacking. It can make rebars in sizes from DN4-40mm. This means it can handle whatever a project needs.

Aoliande’s machines are built smart. For example, the yarn frame is easy to put together. The dipping tank soaks fibers well. The oven has clever controls for perfect heating. Plus, the cutting saw makes sure rebars are the exact length needed. These features make the process smooth and trustworthy.

Commitment to Quality and Innovation in Manufacturing Solutions

Aoliande is all about quality and new ideas. Its FRP rebar machines use pultrusion technology. This pulls fibers through a resin bath and shapes them in a hot mold. It makes strong, even rebars. The machines also let customers pick what they need, so every project gets the right product.

Plus, Aoliande’s machines have cool features. For example, they have speed controls to change how fast they work. The ovens are made for easy cleaning, which saves time. These smart ideas show Aoliande’s focus on making reliable, efficient machines that help customers do great work.

For inquiries about our products or services:

WhatsApp: +86-13363884492 Email: belen@aldfrp.com

FAQ

Q: What is FRP rebar?

A: FRP (Fiber Reinforced Polymer) rebar is a tough material made from fibers in a plastic base. It’s used to make concrete stronger.

Q: What are the disadvantages of FRP rebar?

A: The FRP rebar is awesome because it does not rust and is light. But it’s stiffer than steel and might not handle fire as well, depending on what it’s made of.

Q: What are the advantages of fiberglass rebar?

A: Fiberglass rebar doesn’t rust, is easy to move, is super strong, and saves money on repairs over time.

Q: What is the difference between FRP and TMT bars?

A: TMT bars are steel and bend well but can rust. FRP bars don’t rust and last longer but aren’t as bendy as TMT bars.