Pultruded FRP composites are changing how people build things. They’re made by pulling fibers through a sticky resin and a hot mold. This creates strong, even shapes like beams or bars. They’re a great alternate to steel because they’re light, tough, and don’t rust.

Why should you care? These materials work well in places where steel fails, like wet or chemical-filled areas. They don’t carry electricity either. For companies wanting strong, low-hassle materials, pultruded FRP composites are a solid pick.

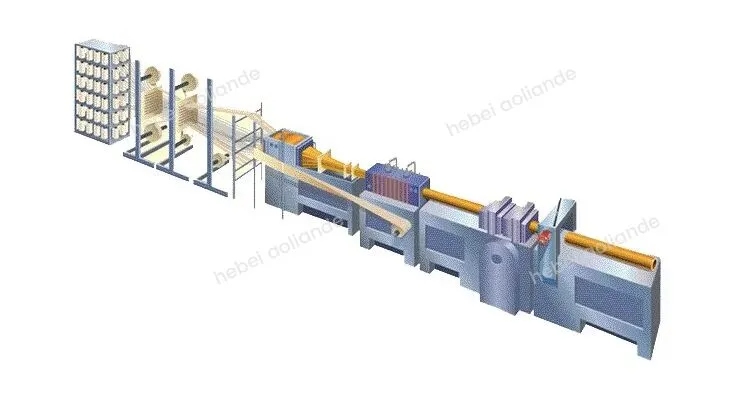

How the Pultrusion Process Works

The process is pretty neat. Fibers, like glass, slide through a resin bath. They get soaked. Then, they go into a heated mold. The heat locks in the shape. A machine pulls everything through smoothly, and a saw cuts the final piece.

This keeps every part consistent. It’s super important for things like bridges or platforms. Good pultrusion machines make sure the results are top-notch.

Why They Beat Steel

Steel’s been the big name in building forever. But it rusts. It’s heavy. It conducts electricity. Pultruded FRP composites fix those problems. They’re way lighter—sometimes 75% less. They don’t rust, even in tough spots. If you need a dependable alternate to steel, these composites are it.

Benefits That Make Pultruded FRP Composites Stand Out

Switching to pultruded FRP composites isn’t just swapping materials. It’s about smarter building. They have cool features that make them popular in construction, energy, and more. Let’s look at why they’re a hit.

Strong but Not Heavy

These composites are super strong for their size. They can match steel’s toughness, pound for pound. So, you get sturdy structures without the extra weight. This makes moving and setting them up easier.

Take a walkway. Using pultruded FRP composites means less support needed. That cuts costs for foundations. They also stay strong in rough weather, making them a great alternate to steel for long-lasting projects.

Saves Money Over Time

At first, pultruded FRP composites might cost more than steel. But think long-term. They’re light, so shipping is cheaper. Setup is quicker, needing fewer workers or machines.

Plus, they don’t need much upkeep. Steel rusts and needs painting. Composites? Just a quick scrub. Over years, this saves a ton, especially in places where stopping work costs big bucks.

Safe and Eco-Friendly

Safety’s a big deal with these composites. They don’t carry electricity. That’s perfect for power plants or places with explosive stuff. They’re also non-magnetic, so they don’t mess with sensitive equipment like telecom gear.

They’re good for the planet too. They last a long time, so there’s less waste. Some resins come from recycled stuff, which helps the environment. For businesses wanting a green image, pultruded FRP composites are a smart alternate to steel.

How Pultruded FRP Composites Stack Up Against Steel

When you compare pultruded FRP composites to steel, it’s more than just strength. Each has strong points. But composites shine in certain spots. Let’s see how they measure up and where they work best.

How They Perform in Real Tests

Studies show these composites can keep up with steel. They’re often just as strong in pulling tests. They bend well under pressure, which is great for places with lots of shaking, like factories.

Steel might win in super heavy crushing tests. But for most jobs, pultruded FRP composites do the trick. They also resist bangs without denting, making them a tough alternate to steel.

Where They’re Awesome

From chemical plants to ocean platforms, these composites are stars. They’re used for pipes and tanks that handle harsh chemicals. In buildings, they make light roofs or walkways that don’t stress the structure.

Even for everyday stuff like bridges or railings, they’re reliable. Their surfaces don’t get slippery when wet. This makes them a safe alternate to steel in public areas.

When Steel’s Still Better

Nothing’s perfect. Pultruded FRP composites can weaken in crazy heat. Steel stays solid there. If you need weird shapes, steel might be easier to work with. For super hot or odd designs, steel could be better. But for most cases, composites are a strong alternate to steel.

| Feature | Pultruded FRP Composites | Steel |

| Weight | Light (up to 75% less) | Heavy |

| Corrosion Resistance | High (no rust) | Low (needs coating) |

| Electrical Conductivity | None | High |

| Maintenance | Low | High |

| Initial Cost | Moderate to High | Low |

| Lifespan in Harsh Environments | Long | Short without protection |

This table shows why pultruded FRP composites are a great alternate to steel in many fields.

Inside the Pultrusion Process

The secret to pultruded FRP composites is the pultrusion process. It’s a mix of tech and precision. Knowing how it works shows why these materials are so dependable.

Step-by-Step Breakdown

It starts with fibers, like glass, pulled from rolls. They dip into a resin bath and get fully soaked. Then, they slide into a hot mold. The heat hardens the resin. A machine pulls it all through at a steady speed. At the end, a saw cuts it to size.

This process makes every piece the same. That’s key for strong structures like platforms or pipes.

Why Machines Matter

Good pultrusion machines keep things consistent. They control how much resin goes on and how fast the fibers move. This stops weak spots. Modern machines tweak settings as they go, so every piece is perfect.

For companies, reliable machines mean happy customers. High-quality output builds your brand in tough markets.

New Ideas in Pultrusion

The tech keeps getting better. New resins set faster, so production speeds up. Some fibers mix different strengths for special jobs. Machines now use less labor thanks to automation.

Eco-friendly resins from plants are also a thing. They cut down on oil use. These updates make pultruded FRP composites an even better alternate to steel.

Industries Using Pultruded FRP Composites

From building sites to power plants, pultruded FRP composites are making a difference. Their flexibility and strength open new doors for all kinds of businesses.

Construction and Infrastructure

Builders use these for walkways, stairs, and railings. They’re light, so they’re easy to put up in tricky spots. In places with earthquakes, they flex instead of break, unlike steel.

Road signs and barriers also use them. They don’t rust, so they last longer in rain or snow. This makes them a cost-saving alternate to steel.

Chemical and Manufacturing

In chemical plants, steel rusts fast. Pultruded FRP composites handle acids and other harsh stuff. Tanks, pipes, and platforms stay strong longer, saving money.

In food factories, they’re easy to clean. This meets health rules without extra work, making them a clean alternate to steel.

Energy and Utilities

Wind turbines use light, strong blades made with pultrusion. Solar farms need supports that don’t rust. Power lines use non-conductive poles to avoid electrical issues.

Oil and gas: Platforms stand up to salty water.

Water treatment: Pipes resist chemicals.

Telecom: Towers don’t block signals.

These show how pultruded FRP composites work as an alternate to steel in many fields.

Success Stories in Action

A chemical plant switched steel grates for pultruded FRP composites. No more rust. Maintenance costs dropped by half. Workers liked how easy they were to handle.

A bridge project used composite beams. They cut weight by 60%. The job finished weeks early. Ten years later, it still looks brand new. That’s a win over steel.

A factory used FRP platforms in wet areas. No electrical shocks. Workers felt safer. It’s a clear example of composites as a strong alternate to steel.

Hebei Aoliande: Your Partner in FRP/GRP Pultrusion Machines

Hebei Aoliande Chemical Equipment Co., LTD., in Hengshui City, China, is a top name in FRP/GRP pultrusion machines. With over 300 workers, including skilled engineers, they make equipment that produces high-quality pultruded FRP composites. Their machines serve clients from the US to India, backed by ISO9001 certification.

They don’t just sell machines. They offer design help, setup support, and material supply. For companies wanting to make composites as an alternate to steel, Aoliande makes it easy.

Conclusion

Pultruded FRP composites are changing the game for building and manufacturing. They’re strong, need little upkeep, and work in many industries. As tech improves, their uses will grow. For businesses looking to stand out, they’re a smart alternate to steel. Ready to try them? Your next project could be a game-changer.

FAQs

Why do pultruded FRP composites beat steel in wet places?

They don’t rust at all. Steel needs coatings to handle moisture or chemicals. This makes composites a lasting alternate to steel.

Are pultruded FRP composites as strong as steel?

Yes, often stronger for their weight. They’re great for light, tough structures as an alternate to steel.

Can pultruded FRP composites take heavy loads like steel?

With good design, they handle big loads well. They’re a solid alternate to steel for beams and supports.

Are pultruded FRP composites easier to set up than steel?

For sure. They’re lighter, so installation is faster. This cuts down on workers and equipment compared to steel.

What industries get the most from pultruded FRP composites as an alternate to steel?

Construction, chemicals, and energy save big on durability and safety.