Fiber-reinforced polymer rebar, often called FRP or GRP rebar, stands out in construction for its strength and resistance to rust. Builders turn to it in harsh settings like coastal bridges or chemical plants where steel fails fast. This piece dives into the FRP rebar manufacturing costs, breaking down what drives expenses and where savings hide. Knowing these details helps firms pick smart paths in production.

Many projects now demand materials that last longer without heavy upkeep. FRP/GRP rebar fits that bill, cutting long-term bills in tough spots. Yet starting production brings its own hurdles. Let’s look closer at the setup and running sides.

Key Factors in Production Setup

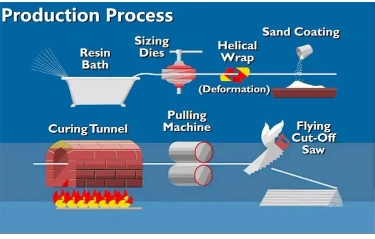

Setting up a line for GRP rebar production efficiency starts with the right gear. Machines handle yarn splitting, dipping in resin, forming, winding, and curing. A basic line might cover diameters from 4mm to 40mm, running two paths at once for steady output.

Costs pile up from raw goods like glass fibers and resins, plus power for heating ovens. A typical oven heats at controlled temps to cure bars solid. Factories see outputs around 500kg per hour on advanced lines, but that depends on setup.

Energy eats into budgets. Heating and traction pull power, often 2.2kW for smaller motors. Factories in cold areas add heating costs, but smart designs recycle heat to trim bills.

Shifting to benefits of FRP rebar machines, these units cut waste. Automatic cutting saws slice bars to exact lengths, reducing scraps. Stacking devices collect pieces neatly, speeding packing. In one factory case, switching to auto stacking dropped labor hours by 30%, freeing workers for other tasks.

A smooth line boosts throughput. Winding devices spin threads at adjustable angles, making bars stronger without extra material. This tweaks cost savings in GRP rebar production by using less fiber per bar.

To connect, grasping these basics leads to crunching numbers on returns.

Breaking Down Initial Investments

Upfront outlays cover machines, molds, and site prep. A full line for ROI in FRP rebar production might hit $100,000 to $300,000, based on scale. Smaller ops start low, producing 4-26mm bars on five lines.

Molds last years with care, but initial buys add up. Steel frames for mandrels cost less than expected, around $5,000 each for standard sizes. Site setup includes space for yarn frames and dipping tanks, needing ventilation to handle resins safely.

Power setups matter. A 380V system runs most units, but wiring and transformers push costs. Factories in industrial zones link to grids easy, keeping installs under $10,000.

Training crews takes time. New hands learn dipping and winding in weeks, but pros hit peak fast. This ties into low cost FRP rebar production by minimizing errors that scrap batches.

Numbers show promise. One plant recouped setup in 18 months through steady orders. Bars sell at premiums over steel, covering higher material spends.

Operational Expenses and Savings

Day-to-day running reveals true efficient GRP rebar manufacturing. Resin and fibers make up 60% of costs. Bulk buys drop prices—glass rovings at $1 per kg, resins around $2.

Labor varies. Auto lines need fewer hands; a four-line setup runs with three operators per shift. Wages in manufacturing hubs sit at $20,000 yearly per worker, but efficiency cuts headcount.

Maintenance keeps lines humming. Ovens and traction units need checks every 500 hours. Parts like seals cost $100 to swap, preventing downtime that halts output.

| Cost Category | Estimated Annual Expense (for medium-scale line) | Potential Savings Strategies |

| Rohstoffe | $200,000 | Bulk purchasing, supplier deals |

| Energy | $50,000 | Heat recycling, efficient motors |

| Labor | $60,000 | Automation, training programs |

| Wartung | $15,000 | Regular inspections, quality parts |

These figures come from plants producing 1,000 tons yearly. Savings kick in with scale—bigger runs spread fixed costs thin.

Water and waste add bits. Curing uses clean water pumps at 560L/h high pressure, but recycling loops cut usage by half.

Linking to bigger picture, these ops build brand strength. Firms known for reliable bars win bids, boosting personal rep in industry circles.

Boosting Efficiency Through Tech

Tech upgrades drive FRP rebar production line setup costs down over time. PLC controls adjust speeds, ensuring even impregnation. This avoids weak spots, reducing rejects to under 5%.

Winding at 45-90 degrees optimizes strength. Bars handle loads better, appealing to builders facing strict codes.

In practice, a bridge project used FRP rebar, slashing corrosion fixes by 40% over steel. Producers highlight this in pitches, elevating brand.

Gear like hydraulic traction pulls steady at 0.1-1.5m/min, matching output needs. Fast pulls for thin bars, slow for thick—flexibility saves time.

Overall, tech turns high setups into quick paybacks.

Long-Term Returns and Market Edge

Looking ahead, GRP rebar machine investment pays through market share. Demand grows in infra, where rust costs billions yearly. FRP lasts decades, cutting replacements.

ROI hits 20-30% yearly for efficient ops. A $200,000 line yields $500,000 revenue at full tilt, minus costs netting profit.

Brands build trust with consistent quality. Suppliers offering full lines, like those at Produkte, help new entrants scale fast.

Firms gain edge by touting eco perks—FRP recycles easier than steel. This appeals in green builds, enhancing rep.

Tying back, smart cost handling fuels growth.

Supplier Spotlight: Hebei Aoliande Chemical Equipment Co., LTD.

As a key player in FRP/GRP rebar machine supply, Hebei Aoliande Chemical Equipment Co., LTD. delivers full production lines. Based in Hengshui City, Hebei Province, China, the company started in 2016. It holds ISO9001, ISO14001, and OHSAS18001 certifications, ensuring quality. With 300 staff, it exports to spots like the USA, Brazil, and India. Services cover tech advice, transport, and install guidance. Check their Über uns for more.

Schlussfolgerung

Wrapping up, a sharp eye on calculating costs for FRP rebar factory reveals paths to profit. From setup to daily runs, efficiencies stack up. Builders and producers alike see value in durable bars that trim long-haul spends. Smart choices here build lasting brands in competitive fields.

Häufig gestellte Fragen

What drives FRP rebar manufacturing costs most?

Raw materials like fibers and resins lead, making 60% of expenses. Energy for curing follows, but recycling heat cuts bills sharp.

How does GRP rebar production efficiency impact ROI?

Higher efficiency means more output per hour, like 500kg, spreading fixed costs thin. This boosts ROI in FRP rebar production to 20-30% yearly.

Are there big cost savings in GRP rebar production from automation?

Yes. Auto lines reduce labor by 30%, minimize waste under 5%, and speed processes. Visit Startseite for line examples.

Was? benefits of FRP rebar machines stand out in harsh sites?

Corrosion resistance slashes maintenance, as seen in coastal bridges saving 40% on fixes. Machines ensure consistent quality for these gains.

How to figure FRP rebar production line setup costs?

Factor machines at $100,000-$300,000, site prep under $10,000, and training. Full details at FRP / GRP Rebar Maschine.